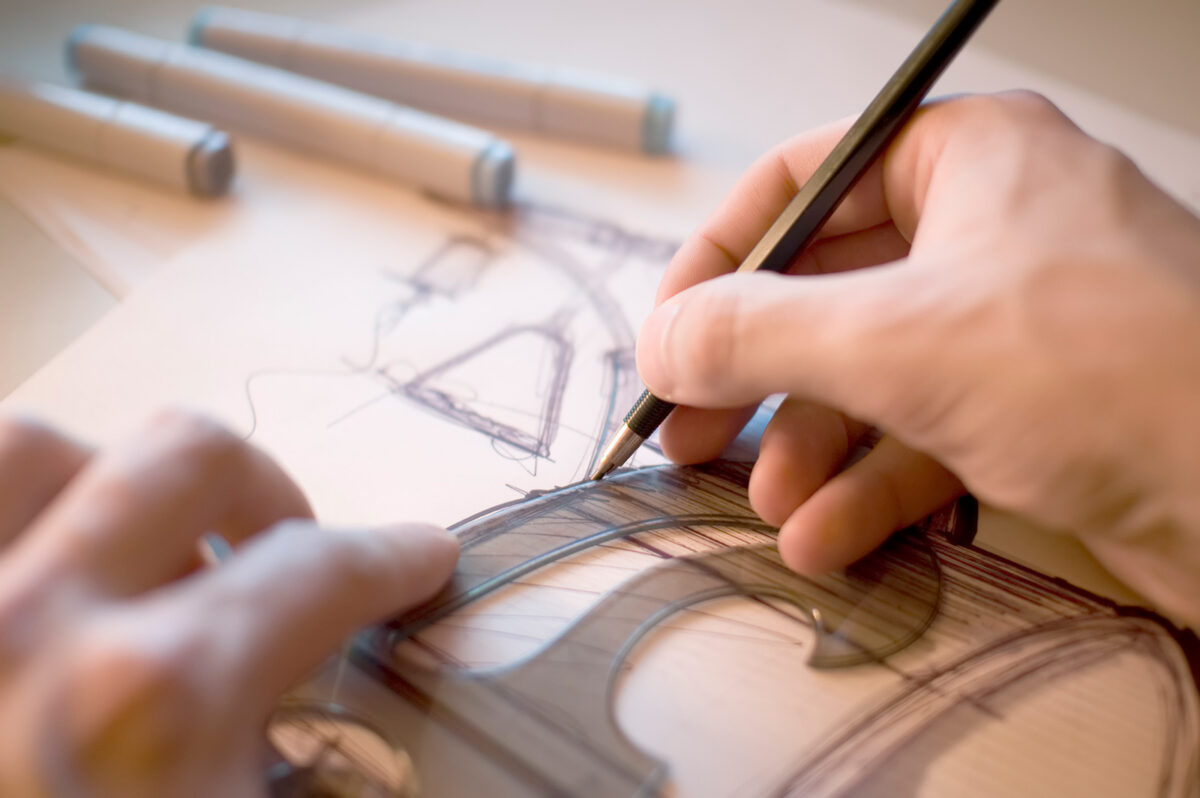

Industrial design or prototyping

Product development is at the heart of innovation and business growth. At MWT Sourcing, we understand the importance of this process in achieving commercial goals and meeting customer needs. Discover our product development process, from the prototyping phase to the conceptualization of the final product, through production cycles and the selection of production partners.

Product Development, as Seen by MWT Sourcing

We leverage our technical expertise and extensive network to manage every phase, from initial development to pre-production, with a focus on superior quality and continuous innovation. This approach, enriched by a collaborative methodology, allows us to offer tailor-made solutions and recommendations tailored to each client’s specific needs.

We ensure that each product or service developed with MWT Sourcing not only meets but exceeds market standards. Our past experiences guarantee the success of a smooth development process, coherent with production tools and potential partners, laying the foundation for optimized and achievable mass production.

MWT Supports You: Product Development

At MWT Sourcing, our approach to product development embraces a 360-degree vision, guided by expertise, innovation, and close collaboration with our partners. We are committed to transforming your ideas into tangible products that meet market needs. Furthermore, we ensure that each product’s production cycle adheres to the highest quality standards at every stage of the development process. You can rely on our recommendations in all process phases, from material selection, techniques, packaging, and conditioning, to offering alternatives to open up discussions.

Research and Development

- Concept Development: Creating the initial product idea.

- Brainstorming: Sessions to generate innovative ideas.

- Standards and Regulations Check: Ensuring product compliance.

- Existing Patent Research: Avoiding intellectual property infringements.

- Preliminary CAD Drawings: Computer-aided design for product visualization.

- Ergonomic Studies: Optimizing user interface for comfort and efficiency.

- Component and Material Selection: Choosing elements for quality and durability.

- Patent Applications: Legal protection for product innovations.

- 3D Rendering/Design: Three-dimensional visualization of the concept.

Engineering

- Numerical Simulations: Virtual tests to predict product behavior.

- Sourcing: Finding suppliers for necessary components.

- Value Analysis: Optimizing costs without compromising quality.

- Cost Estimation: Preliminary calculation of production expenses.

Industrial Design and Conception

- Integration of Industrial Design and Engineering: Combining aesthetic and functional aspects.

- Modeling: Creating digital models for visualization.

- Prototyping: Producing test versions of the product for evaluation.

- Testing: Verifying performance and safety.

- Technical Manuals: Documentation for users and maintenance.

Manufacturing/Market Launch

- Tooling: Creating specific tools for production.

- Pre-production: Limited series manufacturing for final adjustments.

- Fine-tuning: Optimizing the product before mass production.

- Quality Control: Checking each product to ensure compliance.

Your Needs, Our Solutions

At MWT Sourcing, our commitment to excellence drives us to offer a comprehensive range of services dedicated to product development, extending from the initial conceptualization phase to rigorous pre-production. We infuse unmatched added value into every project by adopting a holistic approach characterized by:

End-to-End Production:

Based on insights from your prior market studies, we handle the design and development phase of the product. We can base it on an existing product, modifying or improving it to suit your needs, or we can start a project from scratch. This step involves transforming ideas into a tangible and functional design. Our specialized industrial design teams work together to develop detailed plans, using CAD software to precisely model every aspect of the product.

Compliance and Quality:

Armed with deep regulatory expertise, we navigate through industry standards to ensure each product not only meets but excels in terms of quality and reliability. This includes constant vigilance on regulatory changes, integration of best practices, and meticulous quality control at every stage. We also work with third-party companies to guarantee total neutrality in decision-making and standards attainment.

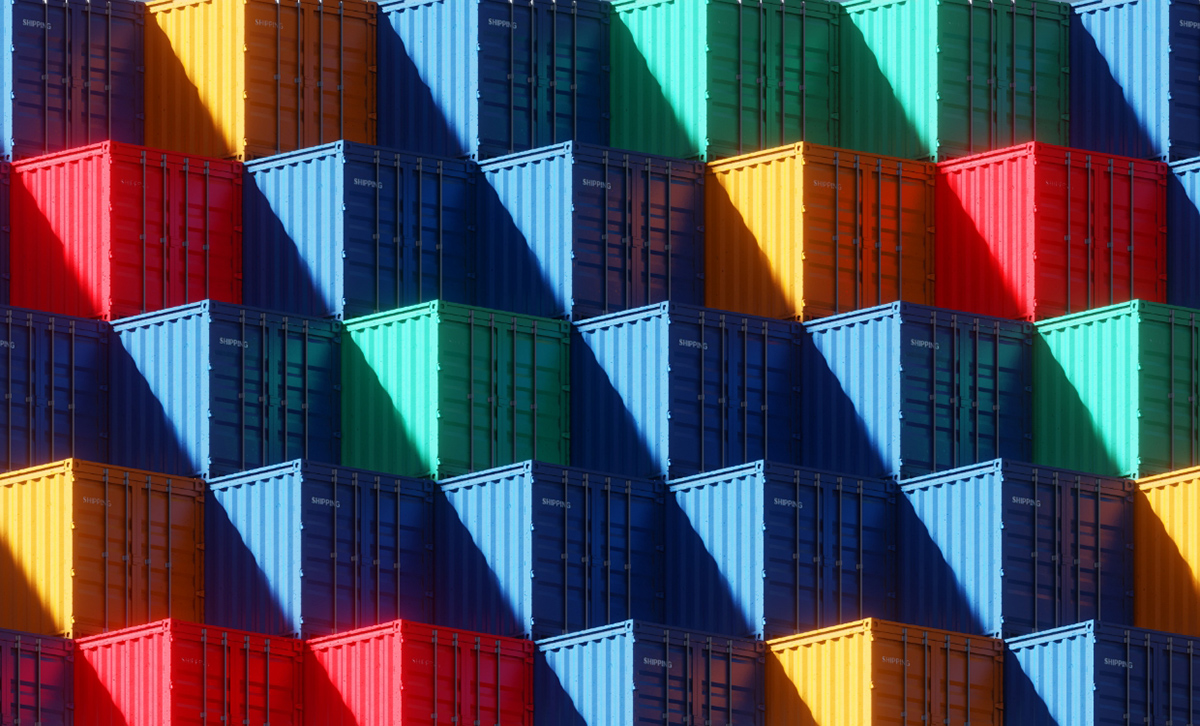

Integrated Logistics:

We refine your supply chain to achieve optimal performance, from material sourcing to shipment consolidation, ensuring smooth and economical distribution of your products to the market.

Customized Solutions:

Every project is unique, and we know it. That’s why we design tailor-made solutions that perfectly align with your specific goals. Whether it’s for process optimization, cost reduction, communication methods, or efficiency improvement, our dedicated team works closely with you to develop an adapted strategy.

Support and Innovation:

Your long-term success is our priority. We stay by your side well after the launch to make modifications and improvements to your products, ensuring they remain relevant and competitive. Our continuous support and innovation advice reflect our commitment to your growth and success.

Do you have a project?

Optimise your procurement strategy with our tailor-made solutions. Our specialists are ready to respond to your specific needs

Frequently Asked Questions about Product Development

What is the importance of prototyping in product development?

Prototyping is crucial as it allows testing ideas, concepts, and functionalities before mass production. It is a step that significantly contributes to innovation by identifying and resolving issues, improving design, and assessing user reactions. This reduces the risks and costs associated with developing new products.

What are common challenges in developing new products and how to overcome them?

Common challenges include identifying market needs, managing costs, meeting deadlines, and ensuring quality. To overcome these, MWT Sourcing adopts an agile and strategic approach, relying on rigorous planning, optimized supplier management, and an iterative development process that incorporates regular testing and feedback.

What are the costs of developing new products?

One of the first resources involves allocating time for the entire product presentation and various back-and-forths. Once the project is validated, we implement all molds, 3D printing, or other methods to define the first physical samples. There is generally a marginal cost at the scale of a mass solution but one that needs to be anticipated upfront. Our mission is to support you as best as possible to avoid errors that often result in unnecessary costs, thereby saving money and time.